Multiple AI Vision

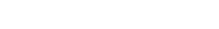

Detects cans that have fallen over on a production line conveyor

The Deep Learning Detect feature

Multiple AI Line Watchers

Uses AI to Monitor Manufacturing Lines and Detect Abnormalities!Alerts Management When Short Stoppages Occur!

Achieves Machine Vision Technology with Surveillance Cameras!

In the field of FA inspection, it is very common to use industrial cameras to detect abnormalities and missing products.

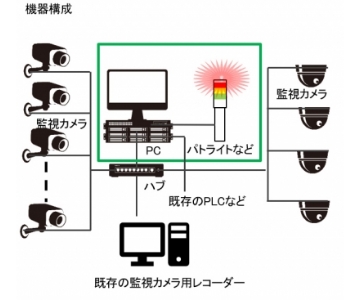

However, when using images from a network camera, it is difficult to recognize images in real time due to the imaging speed and streaming format. As a result, network cameras are not suitable for complex image processing, causing many people to give up on detection with existing surveillance cameras and consider the introduction of an inspection device using an industrial camera. Our company’s Multiple AI Vision connects existing surveillance cameras to imaging devices to achieve the image inspection typically performed by industrial cameras but with surveillance cameras instead.

Features

- Can connect to ONVIF supported network cameras

- Uses AI to create learning-based algorithms that are utilized to detect abnormalities in production lines

- Allows for the creation of customized recognition algorithms using development tools

- Easily integrates with existing equipment

Video

In the field of FA inspection, it is very common to use industrial cameras to detect abnormalities and missing products.

However, when using images from a network camera, it is difficult to recognize images in real time due to the imaging speed and streaming format. As a result, network cameras are not suitable for complex image processing, causing many people to give up on detection with existing surveillance cameras and consider the introduction of an inspection device using an industrial camera. Our company’s Multiple AI Vision connects existing surveillance cameras to imaging devices to achieve the image inspection typically performed by industrial cameras but with surveillance cameras instead.

Application Examples

You can do all of this using security camera video!

Detects abnormal direction of product on a production line (Ex.: toppled cans, line blockages, etc.)Deep Learning Classification

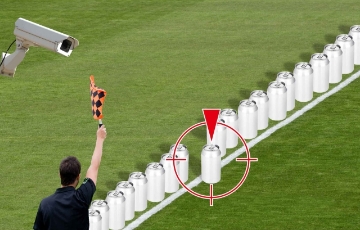

Detects cap abnormalities on bottle manufacturing lines The Deep Learning Detect feature/Classification

Case Studies

Detecting “short stoppages” caused by blockage on a production line

A video of the detection target is in the top left part of the screen and the detected image is the bottom left. This time, the system detected a blockage in the line. When there are 3 or more trays in the specified area, the system marks it as NG. When an NG error occurs, the most recent NG image is displayed on the detection screen (bottom left) and a log is displayed near the bottom of the screen. If you click that NG log entry, a video that starts 10 seconds before the NG error occurred is played on the right side of the screen. You can change the length of the video showing when the NG error occurred by entering the time (in seconds) on the settings screen.

Detecting blockages on a production line

The system learns the position of workpieces and tracks them from about 30 images of the workpieces flowing down the conveyor.

If there are multiple trays within a specific range, the system will produce an NG alert.

NG alerts can also be output via PLC.

Detecting intrusion in a specific area

The system detects intrusion into a specific area using the same method that it uses to detect blockages on a production line.

A network camera is connected to an image processing PC, and the results that were determined by the image processing PC alert the operator to abnormalities via a signal tower or other type of warning beacon.

Learning screen (tray tracking)

A detection algorithm called Deep Learning LocationPoint was used for object tracking and is used to detect clogging on this tray.

With this algorithm, clicking on a tray adds annotations to a tray from previously captured images, allowing the algorithm to learn in a relatively short amount of time.

Other detection examples

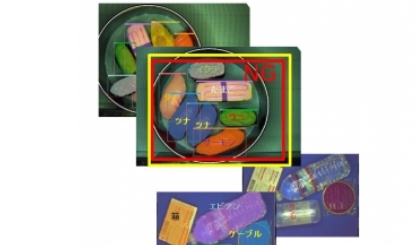

Deep Learning Segment instances are used to determine item types when the workpieces being detected are mixed together.

The algorithm learns by individually annotating each of the workpieces that are mixed together. The algorithm can determine training images with about 30 to 60 images, but the operator must diligently make annotations for the algorithm to learn. Segment instances are the toughest to learn. As for the detection of work errors, there are methods to determine NG workpieces by having the algorithm learn the correct orientation of a workpiece, and there are cases in which this is determined by learning individual NG parts.

Determining product type

The system learns the color, shape, and other features of each product to determine the type of product.

After determining the types, the system checks for differences in quality and other factors to detect missing items.

Deep Learning Segment instances are used to determine the types of items that are present among mixed products.

Detecting intrusion in a specific area

The system detects errors in picking or placing from the position of the operator’s hand or other markers.

Please feel free to contact us if you have any questions.

Contact Us

Feel free to contact us with any questions or concerns

Contact Us