Recognize and inspect printed variable characters on captured images.

A line sensor camera or CIS camera is used to scan the entire surface of a wide print, ranging in width from 300 mm to 600 mm, and it inspects the readability of multiple areas all at once.

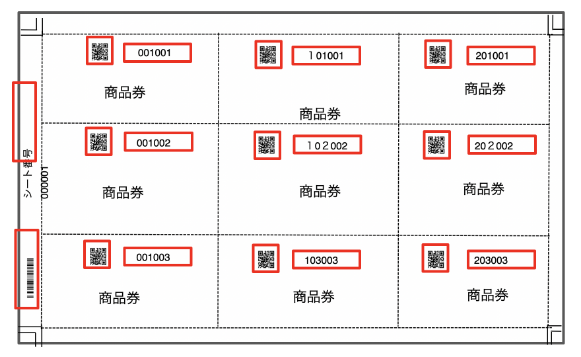

Readability check can be performed at the same time for dozens of target items printed on multi-imposition layout , such as number readability check of gift certificates and readability inspection of labels for sales promotions.

By verifying against planned data (CSV etc.), it is even possible to manage missing number, dulicate numbers and other undesired defects.

CIS (contact image sensor) allows for compact installaltion even in a location that has limited space.