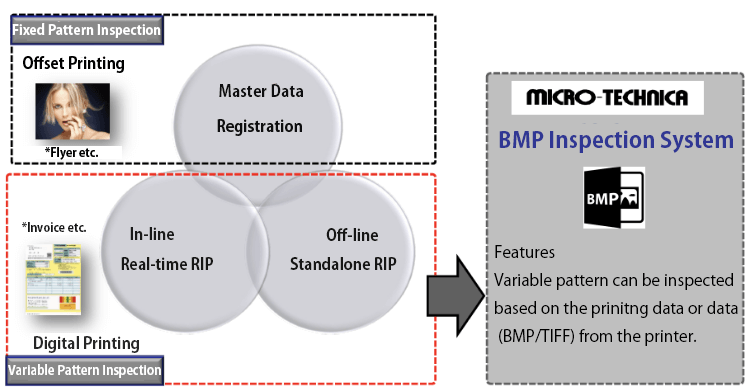

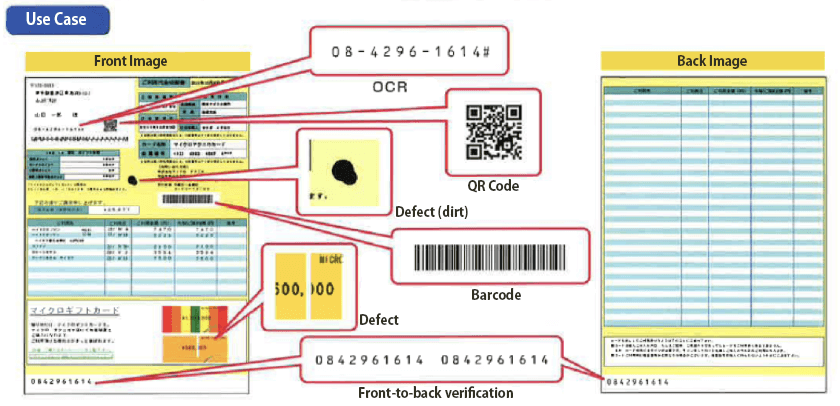

Extract density, and detect various defects such as dirt of high speed color printing.

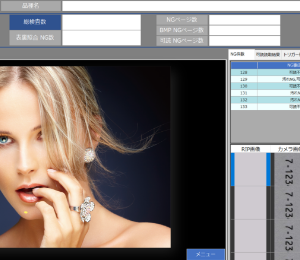

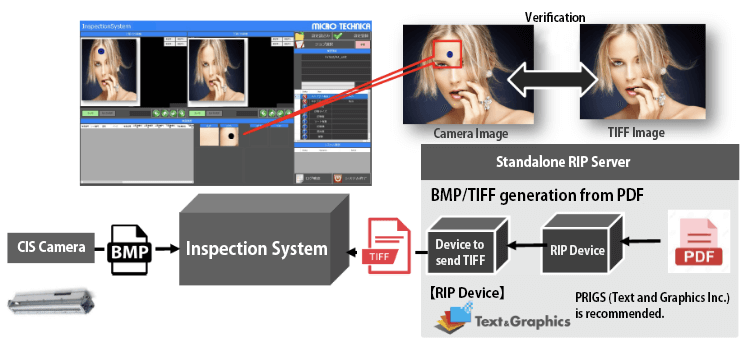

Our bitmap inspection equipment performs “verification of full variable printing by setting printing variable data as a good data”.

Instead of registering a single good item as master, this device can take variable data as a good data to allow for verification on all pages of variable printing.